With the rapid development of industrial automation and informationization, industrial control motherboards have been widely used in many fields. Among them, dynamic loop monitoring is an important part of industrial control, which can monitor the operation status of equipment in real time, find and deal with abnormalities in a timely manner to ensure the stability and reliability of equipment. In this paper, we will introduce the application of industrial control motherboards in dynamic loop monitoring.

1、Industrial Control Motherboard Overview

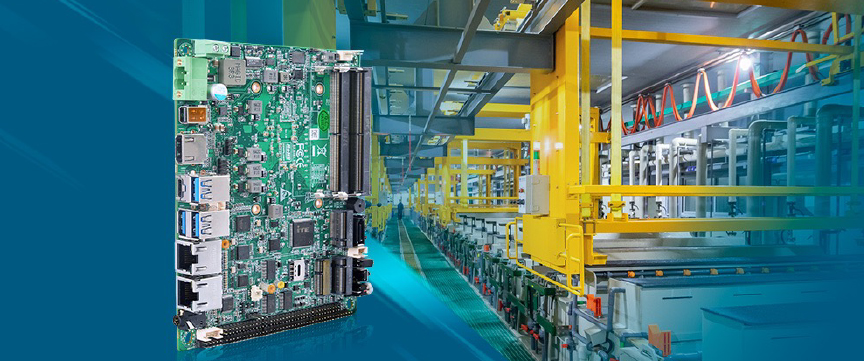

Industrial control motherboard is a kind of computer motherboard designed for industrial environment, featuring high reliability, high stability and powerful data processing capability. It can be connected with various sensors, actuators and other equipment to realize data acquisition, processing and control. In the dynamic ring monitoring, the industrial control motherboard can be used as the central controller to process and analyze the data collected by various sensors, and realize the real-time monitoring of the operating status of the equipment.

2、Components of the dynamic environment monitoring system

The dynamic loop monitoring system is mainly composed of sensors, data acquisition module, data processing module and human-machine interface. Sensors are used to collect data on the operating status of the equipment, such as temperature, humidity, pressure, vibration, etc.; the data acquisition module is responsible for converting the sensor data into computer-recognizable signals and carrying out preliminary processing; the data processing module further analyzes and processes the collected data to determine whether the operating status of the equipment is normal or not; and the human-machine interface is used to display the processed data and alarm information, which is convenient for the user to operate and maintain the system. The human-machine interface is used to display the processed data and alarm information, which is convenient for users to operate and maintain.

3、Application of industrial control motherboards in dynamic loop monitoring

Data Acquisition and Processing

Industrial control motherboards can collect real-time data on the operating status of equipment by connecting various types of sensors and data acquisition modules. After preliminary processing, these data are transmitted to the data processing module for analysis and processing via bus or network. The high-performance data processing capability of the industrial control motherboard can ensure the real-time and accuracy of the data.

Condition monitoring and fault diagnosis

The data processing module analyzes the collected data in depth to determine whether the operating status of the equipment is normal. If an abnormal situation occurs, the industrial control motherboard will trigger the alarm mechanism and display the alarm information and troubleshooting results through the human-machine interface, which facilitates users to find and deal with the problem in time. At the same time, the industrial control motherboard can also analyze the historical data of the equipment and predict the possible failures and potential risks of the equipment.

Remote monitoring and intelligent management

Industrial control motherboards support a variety of communication protocols and network interfaces to achieve remote monitoring and intelligent management of equipment. Managers can view the operating status and alarm information of the equipment anytime and anywhere through the Internet or mobile devices to realize remote monitoring and maintenance. At the same time, the industrial control motherboard can also be linked with other intelligent devices to achieve automated control and management of equipment.

In summary, the industrial control motherboard has a wide range of application prospects in dynamic ring monitoring. It can real-time monitor the operating status of the equipment, timely detection and treatment of abnormalities, to ensure the stability and reliability of the equipment. At the same time, the industrial control motherboard also supports remote monitoring and intelligent management, which improves the maintainability and management efficiency of the equipment. With the continuous development of industrial automation and informationization, industrial control motherboards will be more widely used in the dynamic ring monitoring and other fields.